About us

G.S.Machineries was started in the year 1999 to build core shooter and other foundry machinery. Since then the company has sold more than 500 machinery in & around India. Our product portfolio includes Sand casting equipment, Aluminium casting equipment, Surface blasting, Band Saws and other special purpose machines. Based on the experience gained from the installed machines and customer feedbacks the company strives to build machines that better fit your production needs and innovate new projects.

Products

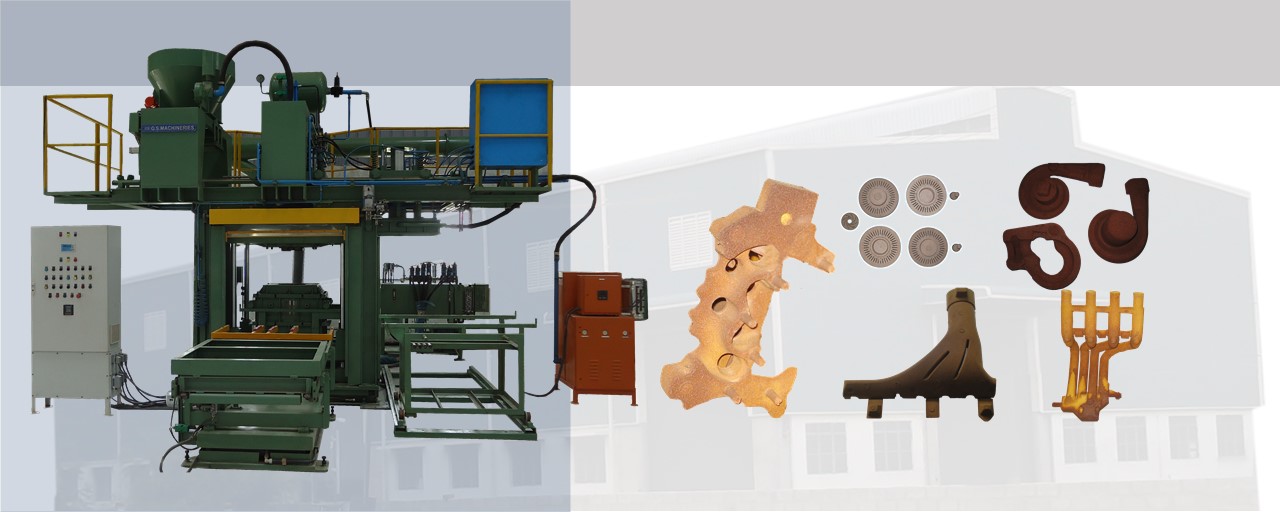

GS Core Shooter

We provide you solutions for both cold box and hot box core shooting technology. We manufacture core shooters that can produce complex core shapes with short cycle time, completely automated till core ejection to reduce the cost of labor. Our Core Shooters produces cores ranging from 0.5 kg to heavy 200 Kg cores.

Combined with our amine scrubber you can reduce the effects of amine for operators during cold box core shooting process.

GS Amine Scrubber

Cold box process is the most commonly used process for the production of sand casting cores throughout the world. They are made by solidifying core sand which is usually quartz or zirconium sand under Tri Methyl Amine fog. Long-term exposure of Tri Methyl Amine fog leads to health hazards for operators. To provide a safe odor free working environment for operators in core shop, the amine gas is to be absorbed from the core shooter and is to neutralize. Neutralization is done with the sulphuric acid solution and results in the formation of amine sulfate which is a neutral salt.

Pneumatic Conveyors

Pneumatic conveyors transport material by suspending them in air stream under positive pressure and delivers them at end points. They ease transport of bulk materials usually sand in foundries and ensures continuous supply of material. We also undertake sand plant orders.

Nitrogen Degassing for Aluminium

Hydrogen gets dissolved in molten aluminum when it gets in contact with water vapor. It has to be removed. If not it will result in the formation of gas porosity and degrades the properties of the cast. The diffused hydrogen is removed by using an inert gas system of Nitrogen or Argon of ultrahigh purity.

Shot and Sand blasting machine

Surface blasting machines (sand/shot) are used to clean, peen, polish thereby improving surface texture. The components are blasted by shots/sand under pneumatic pressure by strategically located nozzles in enclosed or open space. Usual blasting mediums are metal beads, sand particles, glass beads, etc.

Special Purpose Machine and Custom Automation

Utilizing our expertise in hydraulics, pneumatics, finite element simulations, gripper design, servos, sensors and intelligent control system we tailor make machines to support your needs and production process.

At GS, we are currently working on a project to build high-pressure molding machines. It will be released shortly