Sand Casting Equipment

Typical sand casting manufacturing process starts from making a sand mould which is negative of the part to be casted. To have hollow cavities in the cast part, cores must be used. The mould and core are fitted together and the molten metal is poured into it. The core is removed after the metal solidifies by vibration.

Based on our experience in the field for 18 years we offer you solutions for Moulding machines, Core shooters, Core sand mixers, Pneumatic conveyors for sand casting process.

Aluminium casting equipment

Aluminum is casted with metal dies. To produce high qualtiy Aluminiun casts, the hydrogen from the moulten metal has to be removed. Hydrogen dissolves when the metal comes in contact with water vapour in air. Hydrogen is removed in the moulten metal by purging with nitrogen gas. This reduces porosity in cast and improves mechanical properties of the casted alumium. Hydrogenis degassed using mobile degassing machines in ladle or directly in the furnace

Our Alumium casting equipment porfolio includes Nitrogen degassing, Gravity die casting and porosity tesing machines.

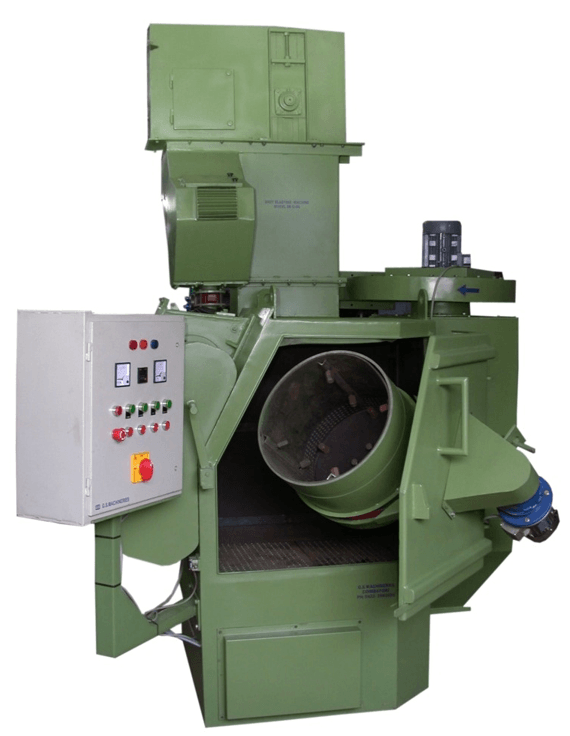

Surface Blasting Equipment

Surface blasting machines (sand / shot) are used to clean, peen, polish or improve surface texture. The components are blasted by shots/sand under pneumatic pressure by strategically located nozzles. They are done in enclosed or open space. Usual blasting mediums include metal beeds, sand particles, glass beeds, etc.

Investment casting equipment

Also called as lost wax process, is a method to produce complex and fine shape under low costs. A mould of the final shape is casted in wax. Then it is coated with ceramic and dried. The wax is then removed from the ceramic in an autoclave by stream under high pressure.

Our Investment casting equipment portfolio includes Autoclave and Wax injection machine

Band Saw

We manufacture vertical band saw for metal cutting used for alumium profiles and wood working process.