Delicate and Precise Finishes Suction Feed:

Suction fed cabinets are generally selected for light – to medium production requirements and limited space. A Suction feed system uses a venturi siphoning action to draw the media into the compressed air stream within the gun nozzle itself. One pass of the nozzle removes foreign matter in seconds and quickly produces a clean uniform surface finish. The use of a media cyclone separator is optional with suction feed systems.

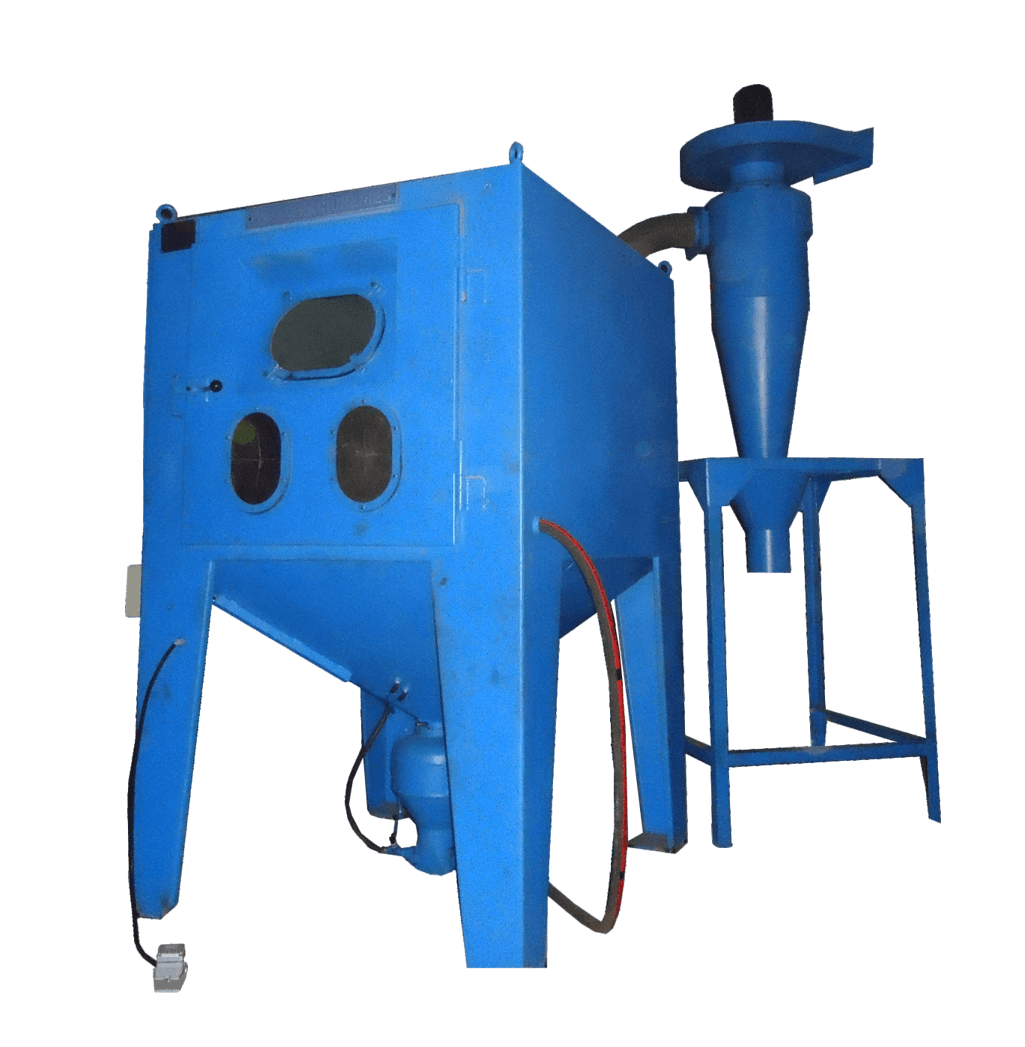

Controlled Power Pressure Feed:

Designed for speed, giving faster cleaning times (up to four times faster than venture system) to meet higher production requirements, pressure feed cabinets are excellenet for emoving tough hard scale deposits particularly within hard-to-reach recessed areas and complex shapes.

The use of pressure vessel forces a flow of media to the blast nozzle at high impact velocities this is particularly important where dense metallic grits are used to impart deep etching prior to bonding or coating

Technical Specification:

| SBE 14 | SBE 10 | SBE 8 | SBE 6 | |

|---|---|---|---|---|

| Internal Blast Chamber Dimensions (WxDxH) mm | 1400x1000x1100 | 100x540x715 | 800x500x600 | 600x500x500 |

| Cabinet Overall Height (mm) | 2400 | 1700 | 1600 | 1500 |

| Side Door(WxH) mm | 1000x1000 | 800x600 | 600x600 | 500x500 |

| Front/Top Door (WxH) mm | - | 500x600 | 500x500 | 500x400 |

| Dust Collector | optional | standard | standard | standard |

| Motor Power | 2.2 KW | 1.5 KW | 0.75 KW | 0.75 KW |

| Air Flow | 11 m³/min | 11 m³/min | 11 m³/min | 7 m³/min |

| Filter Air | 9.3 m² | 3.2 m² | 1.8 m² | 1.8 m² |

| Filter type | Fabric | Fabric | Fabric | Fabric |

| Filter Clamping System | Manual Shake/ Pulse Air | Manual Shake/ Pulse Air | Manual Shake | Manual Shake |

Send us an email for further technical assistance or quotation with the Model name. Our Technical team will contact you as soon as possible. Contact details are available in the contact us link.